Although rock wool and glass wool are both common inorganic fiber materials in the field of building thermal insulation, they have different focuses in terms of raw material composition, manufacturing process, physical properties, fire resistance, acoustic performance, environmental protection characteristics and cost: rock wool uses basalt as the main raw material, with high density, high temperature resistance and excellent sound insulation performance; while glass wool is mainly made of glass slag or quartz sand, with low density, lower thermal conductivity, easy processing and better environmental protection.

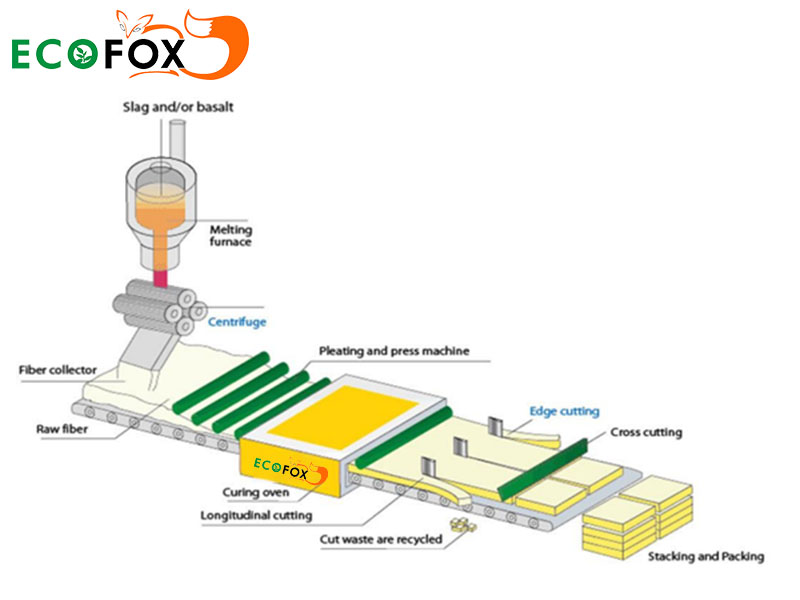

Rock wool is an inorganic fiber insulation material made of natural basalt or limestone as the main raw material. It is centrifuged into fibers after high-temperature melting, and then solidified by adding binders and dust-proof oil.

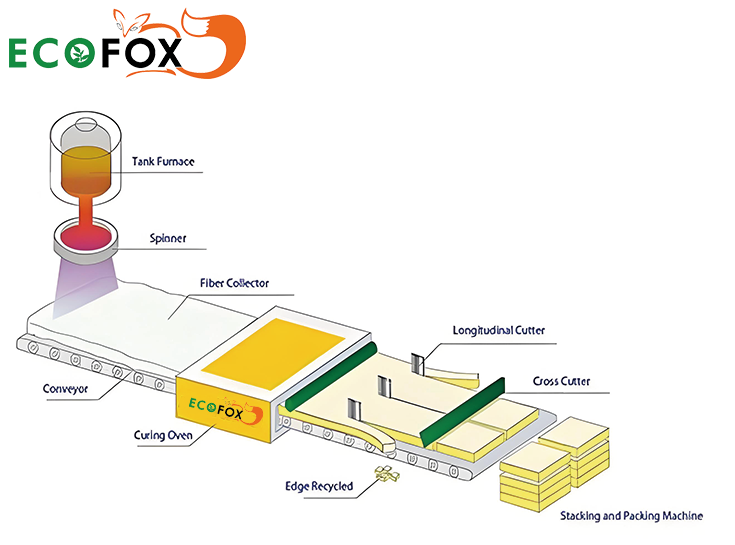

The main raw materials of glass wool are recycled glass slag, quartz sand, dolomite, etc. After high-temperature melting in a glass melting furnace, it is made into felt or plate-like products using fiber-forming technology. Compared with rock wool, it has the characteristics of less slag ball content and finer fiber diameter.

Rock wool preparation: basalt is melted at a high temperature of about 1,450℃, and then centrifugally formed into fibers, sprayed with binders, and cured to form, finally obtaining dense and tough wool felt or sheets.

Glass wool preparation: glass raw materials are mixed with flux, melted in a furnace at about 1,400℃, drawn through a fiber forming process, sprayed with thermosetting, environmentally friendly adhesive,s and cured to obtain soft and cuttable felt rolls or sheets.

The volume density of glass wool is generally 10–100 kg/m³, which is a lightweight insulation material that is easy to carry and cut.

Rock wool usually has a density range of 40–200 kg/m³, which is more compact, but also heavier, and requires higher structural load-bearing during installation.

The thermal conductivity of glass wool is as low as 0.035 W/m·K, with excellent thermal resistance, which can reduce building energy consumption.

Rock wool has a slightly higher thermal conductivity, generally around 0.040 W/m·K, but it can still provide good insulation under the same thickness conditions.

The maximum operating temperature of rock wool can reach 600–730 ℃. It has excellent high-temperature resistance and fire resistance, and can be used as fireproof partitions and pipe insulation.

The thermal shrinkage temperature of glass wool is about 260–270 ℃, which is more suitable for general building insulation and low-temperature pipe insulation.

Glass wool fibers are porous and highly tough. The sound absorption coefficient of the conventional 24 kg/m³ specification at a thickness of 50 mm can reach 0.97, which is suitable for spaces with high requirements for sound environment.

Due to the law of quality, rock wool with higher density has a better sound insulation effect at the same thickness, especially suitable for industrial or commercial places where noise needs to be strictly controlled.

Rock wool itself has a certain degree of hydrophobicity, but due to its high density and high water absorption rate, it dries slowly after contact with water, which may affect the thermal insulation performance.

Glass wool has low density and low water absorption. It can effectively prevent moisture when combined with aluminum foil or moisture-proof membrane surface materials, and is more suitable for humid environments.

Rock wool products can contain more than 70% recycled basalt, but their fibers are not biodegradable.

20%-30% recycled glass slag is used in the manufacture of glass wool. The fibers can be degraded under certain conditions, and the environmental protection is slightly better.

Both are Class A non-combustible materials and do not contain asbestos, but protection must be worn during production and construction to avoid fiber scattering and causing skin or respiratory discomfort.

Glass wool: Insulation of steel structure factory roofs and walls, sound insulation renovation of recording studios and homes, and energy-saving and insulation of general buildings.

Rock wool: High-temperature pipelines, chemical equipment, fire partitions, firewalls, and advanced sound insulation walls, etc., which have high requirements for fire resistance and sound insulation.

Due to different raw materials and processes, the cost of rock wool is usually about 25%-50% higher than that of glass wool, but it can reflect a higher added value in terms of fire resistance and sound insulation.

Glass wool is moderately priced and flexible to process. It is suitable for large-scale rapid construction scenarios and has a high cost-effectiveness ratio.

Rock wool boards should be fixed by nailing to ensure structural safety; glass wool felts need to be anchored and constructed with moisture-proof layers to avoid sinking due to moisture.

Check the integrity of the insulation layer regularly and clean the surface dust in time to ensure long-term stable performance.

Combined with the above comparison, it can be seen that rock wool and glass wool each have their own advantages: rock wool is known for its excellent high temperature resistance, fire resistance and sound insulation performance, and is suitable for high-end and special working conditions projects; glass wool is more suitable for general building energy conservation and acoustic reconstruction due to its low thermal conductivity, light weight, easy cutting, environmentally friendly and degradable, and cost advantages. The selection of materials for the project should be based on actual needs, and comprehensive consideration should be given to performance, cost, and construction convenience to achieve the best energy-saving and comfort effects.

If you have purchase needs for high-quality rock wool and glass wool or want to learn more about the products, please contact our EcoFox insulation team.